Researchers from the U.S. Department of Agriculture’s Agricultural Research Service Investigate the Quality Deterioration of Grape Tomatoes Treated with High Ozone Concentrations To Reduce Salmonella Populations

Edited from the published paper written by Lin Wang, Xuetong Fan, Kimberly Sokorai, and Joseph Sites

The problem

The consumption of fresh produce is growing in the United State and unfortunately this has been accompanied by an increase in the number of food-borne illness outbreaks. From 2004 to 2012 there were 377 reported food-borne illness outbreaks associated with the consumption of produce in the United States. These outbreaks were caused by pathogens such as Salmonella, Escherichia coli, and Listeria monocytogenes. In 2011, enhanced surveillance and improved pre- and post-harvest food safety practices were put into place and the number of Salmonella outbreaks linked to tomatoes began to decrease. The use of ozone has been evaluated as a potential treatment technique to prevent future outbreaks of food-borne illness. The FDA approved the use of ozone as a direct additive for food treatment in 2001. The use of gaseous ozone and aqueous ozone is now commonplace in the treatment of produce.

Researchers from the USDA’s Agricultural Research Service decided to study the treatment of grape tomatoes using high ozone concentrations, in particular focusing on the role the ozone played in inactivating Salmonella, yeasts and molds on the tomatoes. The impact of the ozone treatment on the fruit sensory and nutritional quality was also observed during 21 days of storage at 10 °C.

The Solution

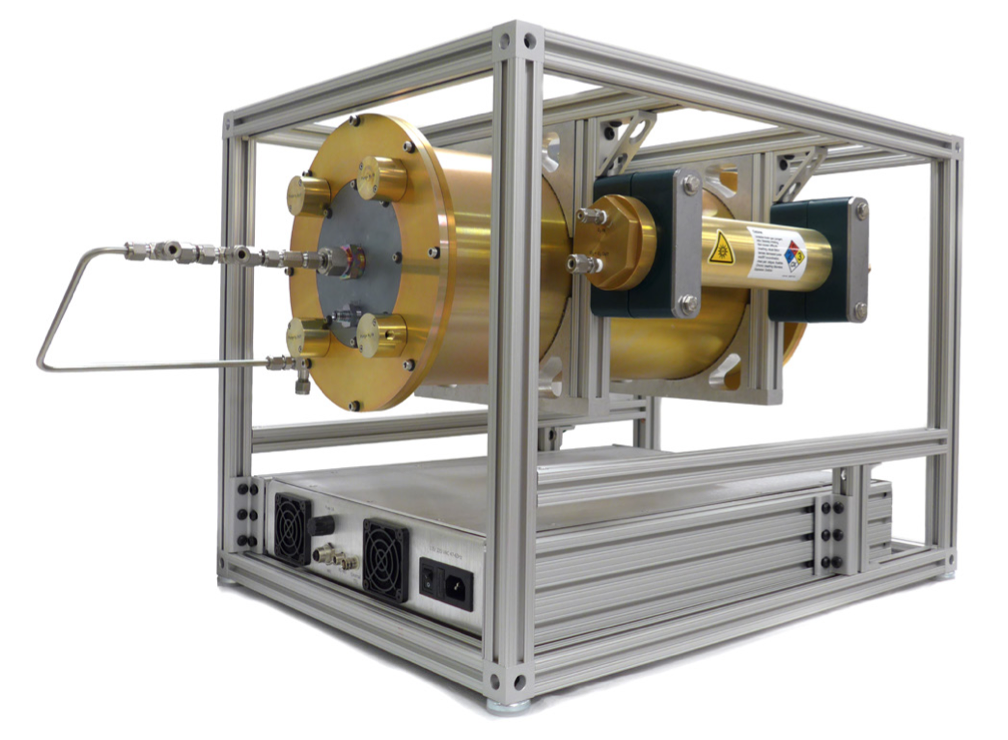

Tomatoes inoculated with Salmonella were exposed to either 1.71 mgL-1, 3.43 mgL-1, or 6.85 mgL-1 of ozone for a time period of either 2 hours or 4 hours. After treatment the tomatoes were placed into storage for 21 days at 10°C. Salmonella populations, sensory properties (appearance of off-odor), total plate count (TPC), mold and yeast count, color, firmness, lycopene content, and ascorbic acid (vitamin C) content were measured on day 1, day 7, day 14, and day 21 of storage. Tomatoes were inoculated with Salmonella by placing a 10 μl bacterial suspension on the stem scar or smooth surface areas of the fruit. Aliquots of the inoculum were placed at five locations on the smooth surface of the fruit to prevent it from running off the sides of the fruit. The ozone treatment set-up for the tomatoes consisted of an ozone generator (NANO, Absolute Ozone, Edmonton, Canada), an ozone monitor (106-MH, 2B Technologies, Boulder, CO, USA), a proportional integral device (PID), a one-gallon treatment jar, and an ozone destruct unit (Ozone Solutions, Hull, IA, USA). Oxygen and nitrogen from pressurized cylinders were mixed and gas flow was controlled by the PID controller and ozone monitor to achieve the three ozone concentrations mentioned above in the treatment jar.

The Results

Ozone treatment was effective in reducing the populations of Salmonella on the grape tomatoes. The reductions of Salmonella populations by 2 hour and 4 hour 6.85 mgL-1 ozone treatment were approximately 2 log CFU fruit−1 on both the smooth surface and stem scar area of tomatoes. However the other ozone treatments (1.71 mgL-1 and 3.43 mgL-1 for 2 hours and 4 hours) did not significantly affect the Salmonella populations on the tomatoes compared to the control. Ozone treatments with 6.85 mgL-1 for 2 hours and 4 hours and 3.43 mgL-1 for 4 hours significantly reduced total plate count on day 1 and day 7 of storage. Yeast and mold count was significantly reduced on day 7 of storage after undergoing 6.85 mgL-1 ozone treatment for 4 hours.

Several measures of fruit quality were assessed. Fruit treated with 3.43 mgL-1 for 4 hours had significantly lower appearance scores than the control on all sampling days except day 1. The 4 hour, 6.85 mgL-1 ozone treatment significantly reduced the appearance scores of grape tomatoes on every sampling day. Tomatoes treated with 3.43 mgL-1 and 6.85 mgL-1 of ozone for 4 hours deteriorated to the point where the fruit was not saleable. Fruit treated with 3.43 mgL-1 for 4 hours had significantly higher off-odor than the control on day 1 and day 14. The off-odor of grape tomatoes treated with 6.85 mgL-1 for 4 hours were significantly higher than the control on all sampling days. Fruit with a redness ratio of 0.95 – 1.21 are acceptable to the USDA. The fruit treated with 3.43 mgL-1 and 6.85 mgL-1 ozone for 4 hours had redness ratios below 0.95 on all sampling days.

All 3.43 mgL-1 and 6.85 mgL-1 ozone treatments led to significant reductions in firmness of grape tomatoes with loss of firmness occurring immediately. Significantly lower lycopene content was observed in fruit treated with 6.85 mgL-1 ozone for 4 hours on day 1. Lower lycopene content was also observed in fruit treated with 3.43 mgL-1 ozone for 2 hours and 6.85 mgL-1 ozone for 4 hours on day 14. After 21 days of storage, fruit treated with 3.43 mgL-1 and 6.85 mgL-1 ozone for 4 hours had only 1/3 of the ascorbic acid content compared to the control.

In sum

High concentrations of gaseous ozone reduced Salmonella populations on both the smooth surface and the stem scar area of tomatoes. The treatments also reduced native microbiota populations during the early period of the storage.

However, gaseous ozone treatments caused damage to tomato quality and nutrients. The damage included appearance changes, development of off-odor, softening, decrease in redness, and loss in ascorbic acid/lycopene content. Therefore high concentrations of ozone used for treatment over a long period of time may not be appropriate to enhance the microbial safety of grape tomatoes without compromising fruit quality.

Click here to view the full paper:

The 2B Tech Instrument’s Role

The Model 106-MH Ozone Monitor was used to measure and control the amount of ozone generated to evaluate its effect on grape tomatoes. The instrument’s wide measurement range of ~0-21.41 mgL-1 (0- 10,000 ppm) allowed a single instrument to control all three of the different ozone levels used during the study. The 2x two-level relays on the Model 106-MH were used to control the output of an ozone generator. These relays also made it possible to keep the ozone output from the ozone generator at a stable level. This was critical toward ensuring the grape tomatoes were exposed to the proper amount of ozone so the researchers could accurately catalog its effect on the fruit. The small size and portability of the Model 106-MH made it easy to pair the monitor with the NANO ozone generator for the purposes of this study.

The Bottom Line

If your application involves monitoring ozone off-gas in a water treatment plant, control of lower concentration ozone generators, monitoring of ozone used for food treatment, or any other research project/ industrial application requiring ozone concentrations between 0-10,000 ppm, then the Model 106-MH Ozone Monitor is right for you. The instrument is offered in either our blue bench-top enclosure (pictured on the left), in our industrial/NEMA wall-mount enclosure, or as an OEM if you would like to integrate the instrument into your own system. With extremely low power requirements and high portability, the instrument can be deployed for a wide variety of ozone-related projects and research studies. The two-level relays previously mentioned allow the instrument to control an ozone generator or an external warning system that can be activated if ozone concentrations exceed a user-defined set point (our Tech Note 45 describes some of these applications of the relays). Please contact 2B Technologies to discuss using the Model 106-MH for your application.