Manufacturers of an Ozone Sterilization System Capitalize on the Value Added from Accurate Ozone Monitoring During their Sterilization Process

The Problem: The Coronavirus pandemic has created a need for businesses, governmental entities, and health-care providers to develop innovative sanitation procedures to ensure the health and safety of their workers and the general population. It has become paramount for sanitation methods to be as effective as possible to prevent the spread of the virus. Traditional sanitation methods such as disinfecting wipes, sprays, treatment with UV light, etc… all have various drawbacks. These include the inability to completely disinfect every surface in a room, labor-intensive application requirements, and the potential for leftover toxic chemicals once the cleaning process is complete. As demand for increased sanitation of indoor spaces has grown during the pandemic, so has the need for a disinfection process that is effective, efficient, and does not leave a trace.

Gas-phase ozone has become one of the leading disinfection solutions in the ongoing battle against COVID-19. The chemical properties of ozone allow the molecule to combat many kinds of virus and bacteria. Ozone is very effective at cleaning all surfaces in a room (including hard-to-reach cracks and crevices) when applied in combination with high humidity. Ozone is a catalytic disinfectant and does not leave behind any chemical residue once the sterilization process is complete.

However the use of ozone is not without its own set of drawbacks. High ozone concentrations in air are toxic to humans; therefore, a room must be completely unoccupied and sealed so that a high enough concentration of ozone can be generated to ensure the virus and/or bacteria has been destroyed. After the ozone treatment, it’s necessary to know when the ozone concentration has dropped to levels that are safe for occupants to re-enter the room. Ozone must be monitored during the entire disinfection process to ensure both of these conditions can be met.

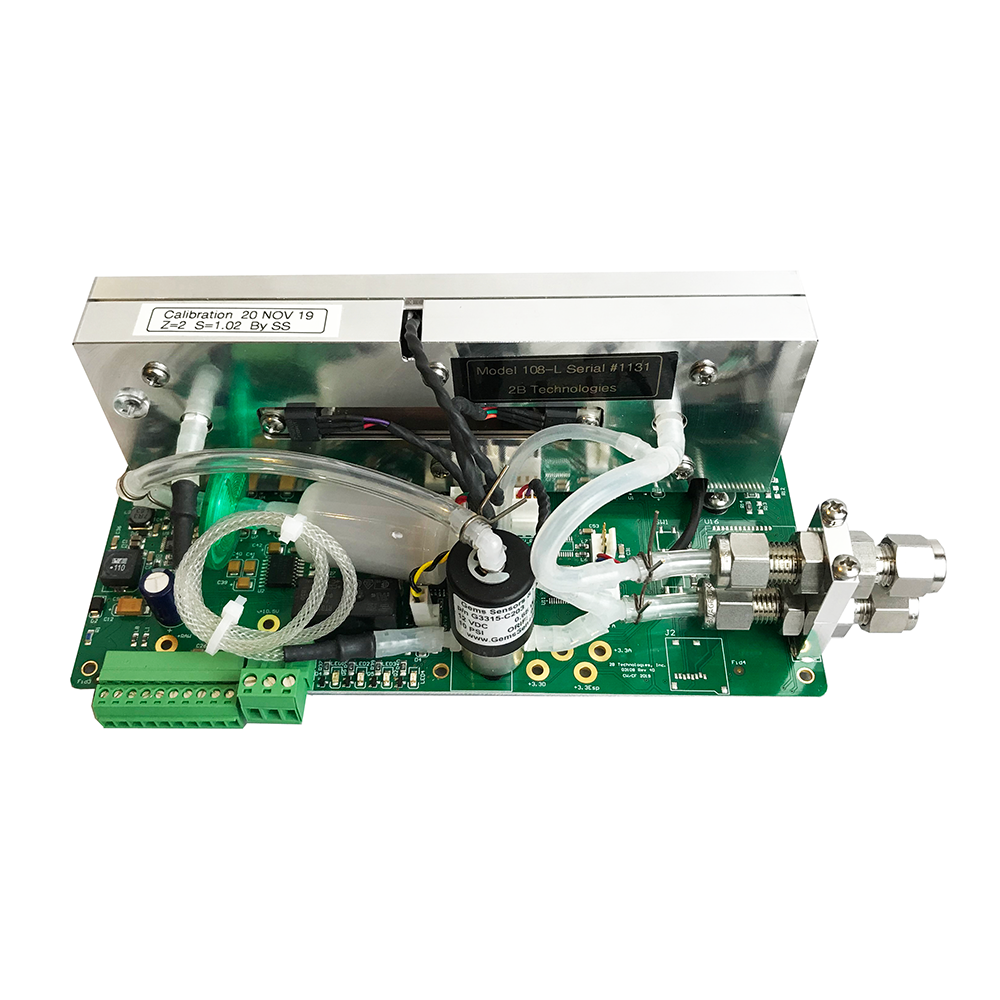

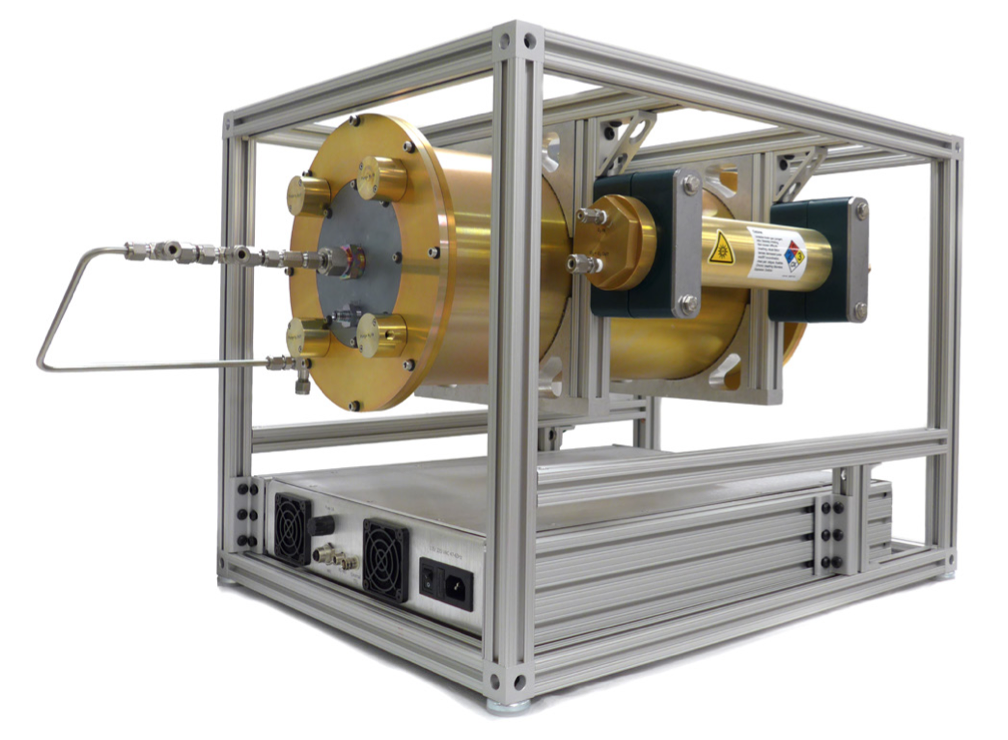

The Solution: An ozone generator manufacturer based out of Europe, STERISAFE ApS, decided that the integration of a UV-absorbance based ozone monitor into their disinfection system was a necessity to ensure the health and safety of their clients. After evaluating a few different ozone monitors, STERISAFE chose to pair the 2B Technologies’ Model 108-L Ozone Monitor with their disinfection system. The standard version of the Model 108-L does not have a pump and is our most “bare-bones” ozone monitor. 2B Technologies created a custom version of the Model 108-L to streamline the integration of the monitor into their product, the STERISAFE PRO. A sheet metal enclosure was added to the ozone monitor to prevent electromagnetic interference from affecting the instrument’s performance. The metal enclosure also made it possible to add a pump to the Model 108-L. With the pump, the customized ozone monitor became an all-inclusive package and no longer relied on the STERISAFE PRO to provide a constant flow of ozone gas to the instrument.

Lastly, the ozone disinfection process employed by the STERISAFE PRO calls for high levels of relative humidity. As part of the integration, an external Nafion assembly is attached to the inlet of the Model 108-L to help the instrument cope with changing humidity conditions. The external Nafion assembly allows the instrument to eliminate any potential water vapor interference from the ozone measurements by equilibrating the relative humidity between both the reference and sample measurement cycles in the ozone monitor. The Nafion assembly is a unique feature of 2B Tech instruments; other small, UV-absorption ozone monitors do not use Nafion and, as a consequence, they experience a large interference due to water vapor in conditions of high relative humidity.

The 2B Tech Instrument’s Role: As previously mentioned, the Model 108-L is integrated into the STERISAFE PRO as a means to monitor ozone during the entire disinfection process. The integrated relay and the wide measurement range of the Model 108-L (0-100 ppm) make it possible for one instrument to serve two purposes critical to the disinfection process. The high end of the measurement range enables the 108-L to alert STERISAFE when ozone concentrations reach a high enough level to ensure effective sterilization. The low end of the measurement range enables the 108-L to identify when ozone concentrations have dropped to a level after disinfection that is safe for people to re-enter the treatment area. The various data outputs offered by the Model 108-L (RS232, 4-20 mA, 0-2.5 V) allowed STERISAFE to integrate data from the ozone monitor along with diagnostic data from their generator. This allows the customer to easily monitor the performance of all aspects of the STERISAFE PRO.

Visit the STERISAFE website for more information about the STERISAFE PRO.

The Bottom Line: The Model 108-L is ideal for integration with an ozone generator in applications that require highly accurate ozone measurements. The Model 108-L is equipped with a two-level relay that can be used for either control or alarm purposes. For example, the relay can be programmed with a user-determined ozone set point to turn off an ozone generator if the measured ozone concentration exceeds the programmed set point, or the relay can turn on an ozone generator if the measured ozone concentration drops below the set point. The use of the relay in this manner allows the 108-L to optimize the efficiency of an ozone generator. Alternatively, the relay can be used to control an external alarm or warning light by employing a similar technique.

The Model 108-L can be ordered with the pump/enclosure as used in the STERISAFE application, without the pump in a truly bare-bones configuration (the standard version), or in a weatherproof/NEMA enclosure as part of the AQLite monitoring package. Many customers have begun to utilize the monitoring capabilities of the 108-L for ambient ozone monitoring applications. Because of the highly accurate nature of the instrument, the United States Environmental Protection Agency has designated the Model 108‑L as a Federal Equivalent Method (FEM) for monitoring ambient ozone. This has led to the instrument being integrated into a mobile monitoring project (described in another Application Note) and in our new AQLite Monitoring Package. The AQLite combines the ozone measurements from the 108-L with meteorological measurements (T, P, RH) and sensor-based measurements for Particulate Matter (PM1, PM2.5, and PM10), Carbon Monoxide (CO), and Carbon Dioxide (CO2).

Whether it’s part of an ambient air quality monitoring system or a component of an industrial ozone disinfection package, the Model 108-L is up for the task. Please contact 2B Technologies to discuss using the Model 108-L for your application today.